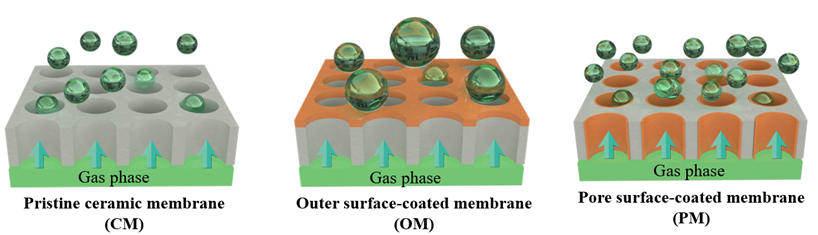

Dr. Shan Xue, a former Ph.D. student and postdoc of Prof. Zhang’s group, now a research scientist at PureNanoTech Inc., recently published her postdoctoral research in Langmuir (https://doi.org/10.1021/acs.langmuir.4c04781), which evaluated the interfacial processes of nanobubble evolution and production across a porous membrane surface. Many operational factors and membrane properties can significantly influence nanobubble production and characteristics. This study examined how membrane pore size, surface hydrophobicity, and gas/water flow conditions affect nanobubble size and concentration. Findings reveal that reducing the ceramic membrane pore size from 200 nm to 10 nm slightly decreased the mean nanobubble diameter, from 115 nm to 89 nm. Furthermore, membranes with a hydrophilic outer surface and hydrophobic pore surface generated smaller nanobubbles with higher concentrations in water. Additionally, a high water cross-flow rate (e.g., >1 L·min⁻¹) increased the nanobubble concentration, though bubble size remained unaffected. In contrast, the gas flow rate had a more pronounced effect. Increasing the gas flow rate from 0.5 to 12 L·min⁻¹ significantly raised the nanobubble concentration from 3.09 × 10⁸ to 1.24 × 10⁹ bubbles·mL⁻¹ while reducing the mean bubble diameter from 100 nm to 79 nm. An interfacial force model was applied to analyze bubble detachment at the membrane pore outlet, considering factors such as gas flow/pressure, surface tension, and shear forces from water flow. These findings offer valuable insights into the mechanisms governing nanobubble generation via gas injection through porous membranes.